Enhance Cement Compressive Strength At All Ages

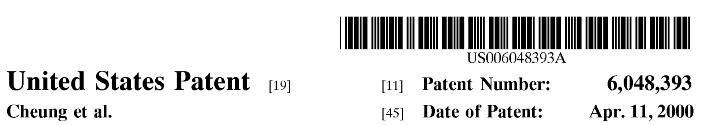

This example illustrates the enhanced compressive strengths of mortars Produced from Six different Portland cements with the addition of DEIPA when compared with cements prepared With TIPA and TEA. Two inch mortar cubes were produced from six commercially available cements using the procedure specified in ASTM C109. Additives were added to the mixing water before the addition of the cement, at a dosage of 0.0001 g of additive per gram of cement. Compressive strengths of the resulting cubes were measured at ages of 1, 3, 7 and 28 days. Table shows the DEIPA is generally superior to TEA and TIPA in its ability to improve early compressive strength (at 1, and 3 day) and also late compressive strength (at 7 and 28 day) properties. Better Finish Surface of Cement

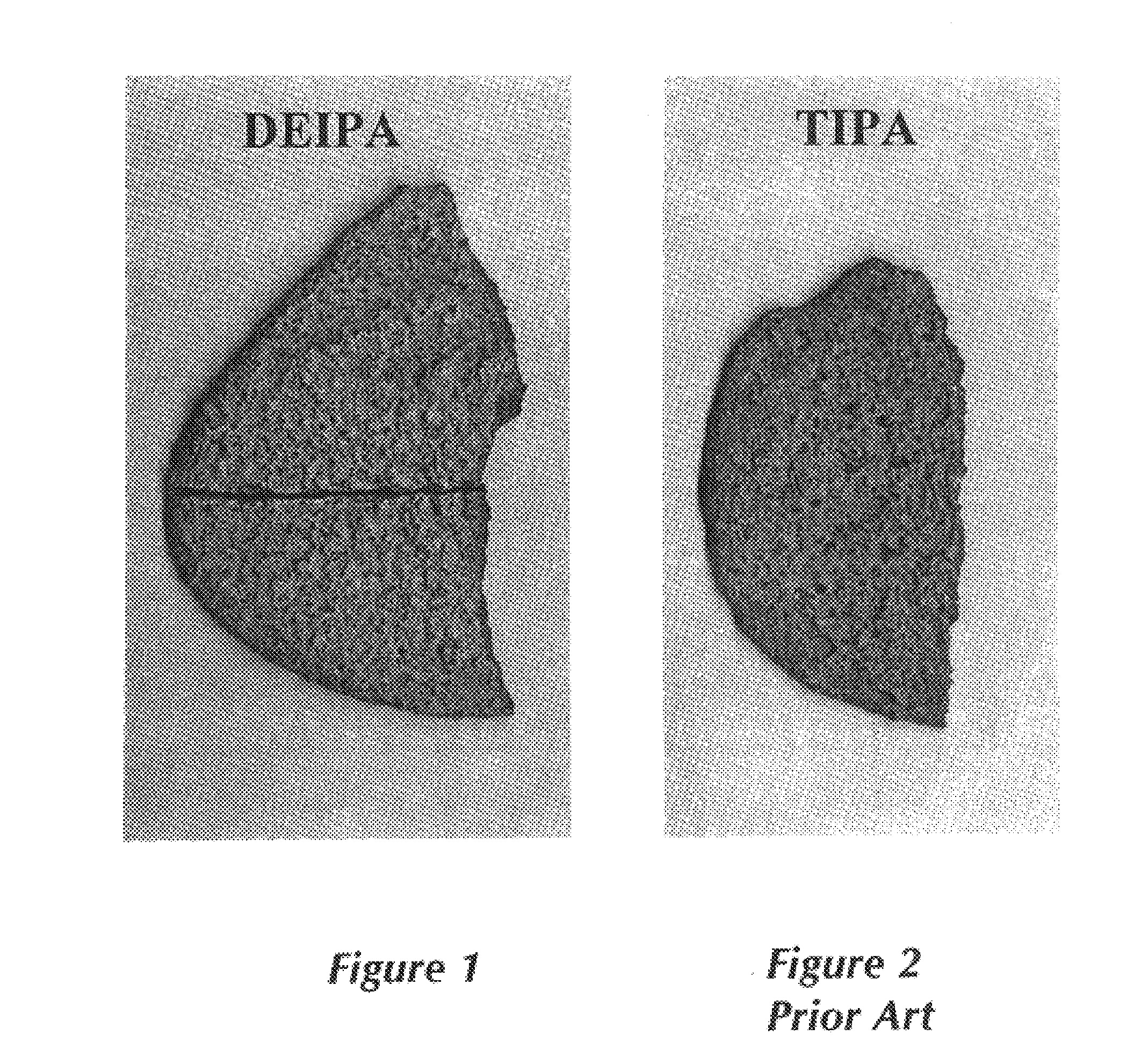

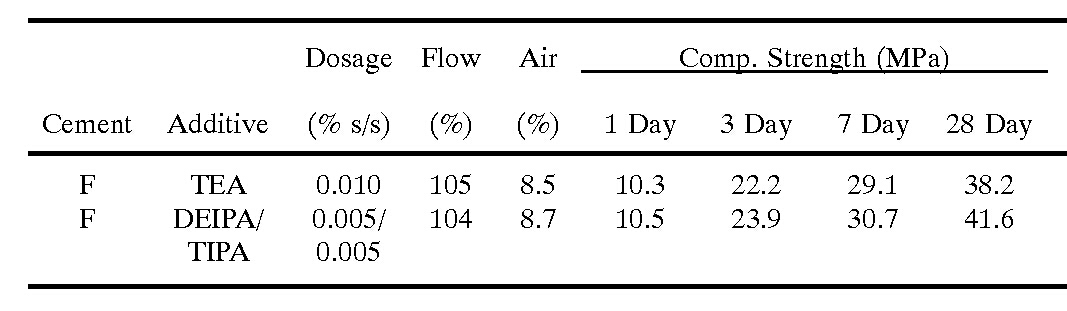

This example illustrates the improved porosity and finish surface of mortars made With DEIPA. Two mortars were made in accordance to EN 196 standard—one containing DEIPA and the other containing an equivalent amount of TIPA for comparison. After determination of the air content,the mortars were poured and allowed to cure for 1 day without tamping or vibration. Electronic reproductions (see FIG. 2) of the surface of each sample show that mortar made with cement interground with triisopropanolamine (TIPA) created many large surface holes and large pores in the mortar. These large holes and pores were, however, not seen with cement made with DEIPA (see FIG. 1). Less Bubbles & Pores in Cement Paste

Saving Cement Setting Time

This example illustrates the unexpected early setting from mortars made with industrial cements interground to equal fineness as determined by Blaine specific area (BSA) measurements With DEIPA and TIPA. The Vicat set-time experiment was conducted using the procedure specified in EN 196. The results are shown in Table. Combinable with TIPA & TEA

This example and Table demonstrate the combinability of DEIPA and TIPA with each other to obtain enhanced strength enhancement. When further used in combination with known additives such as soluble alkali metal salt set accelerators and set retarders enhancement of cement properties are obtained. (All the above data are cited from below patent document,for your reference only.)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||